The House That Macy's Built

Americans are impulse buyers. We buy everything imaginable on impulse--food, clothing, computers, gift cards, cars even.....but a vacation home? Believe it or not, Macy's tried to extend this American way of consuming to the housing market, with a little-known project entitled "Leisurama". The scheme was this--offer a modestly-priced turn-key vacation home in Montauk within walking distance to the beach that the average New Yorker could afford. Add to this a complete model of a home for viewing on the 9th floor of their flagship store, and have sales associates standing by ready to take orders before people could think twice about it or even VISIT THE SITE!!!!! The shocking thing.....in the early 1960s, it almost worked.

The Location

These homes were located in Culloden Point in Montauk, Long Island. Because of their identical appearance and the iconic front window, the neighborhood was soon known as the "Levittown at the beach". Culloden was the ideal place as the land could be acquired relatively cheaply because of its location on the north side of the island and its relative proximity to Camp Hero (with its spooky tales of invisibility, mind control, time travel and "Reptoids"). The Montauk location was also convenient for most New Yorkers - a fairly short drive or a short trip on the Long Island Railroad. Culloden was the bargain beach with all the glamor of the Hamptons.

|

| 1965 view of the development. The landscape has since grown in. |

|

| Original design concept for the Leisurama |

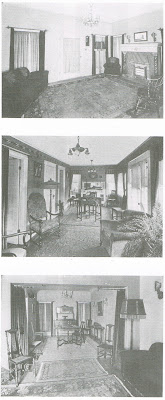

The Design The Leisurama homes had a striking modern appearance. The front window and the carport figured prominently in the design of all the Leisuramas. The homes were one story with a low-pitched roof which also added to the modernist appearance. Because the homes weren't really designed for permanent living, the footprint of the homes was kept small--two bedrooms was a big Leisurama. Like many other mass-produced houses, they were constructed on slab constructions. There were three models constructed--the "Convertible", the "Expanded Convertible", and the "Villa" (see below for floor plans). The Covertible and Expanded Convertible were offered for sale. The Villa was designed as a rental unit for people to test-drive the Leisurama lifestyle.

|

| The Convertible |

|

| The Expanded Convertible |

Pricing and Sales

The cost of one of these Leisurama homes? $12,900--furnished in every way imaginable down to the linens and toothbrushes. You chose from one of two floorplans (the convertible or the expanded convertible), you chose one of four color schemes, you paid your deposit and then.....you waited to pick up your key! Macy's boasted that all you needed to bring was the food for the refrigerator...which was included. In fact, a full line of General Electric appliances were included, even a combination washer/dryer. The houses contained a MURPHY BED! Exciting but impractical, according to those who populated the Leisuramas.

|

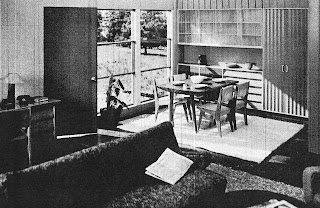

| Leisurama Interior - Featuring the Murphy Bed! |

|

| Photo of a complete Leisurama on the 9th Floor of Macy's Herald Square |

Leisurama's Demise and Legacy

The price was a little too good to be true...for the seller, anyway. Macy's and All-State Properties lost money on each house. This, more than anything, led to the quick demise of the Leisurama experiment. Construction problems also plagued the project. The project had grand aspirations, but only about 200 Leisuramas were built. Many still survive and dot the Culloden Shores landscape, but most have been modified from their original appearance. Some have been sold as "tear downs", others have been enlarged to reflect the current "McMansion" garishness that is typical of contemporary shore homes. Leisurama Homes reflect something that currently doesn't exist in the Northeast shore culture anymore--modest, affordable vacation homes. Take a trip on Long Island or down the New Jersey shoreline and look at the beachfront monstrosities--what normal person can maintain a second home of that magnitude? Or even a primary magnitude???? The Leisurama wasn't perfect, but it was a great way to have a modest getaway home that exhibits modern design.

Models and Floor Plans

Below are the floor plans of the three models as they appeared in a Macy's sales brochure.