Have you ever been inside a barn--a traditional post and beam barn? Barns are amazing feats of engineering and construction. They have soaring ceilings, large usable spaces, and very few (if any) interior walls to break the space up. How is this accomplished? A traditional barn is actually a self-supporting exterior skeleton that is enclosed merely by non-structural sheathing, making interior walls unnecessary for structural purposes. It is this concept, along with some other prefabrication techniques, that led Carl Koch and his associates to design and market one of the most successful enterprises in mass-produced houses--the Techbuilt House.

Concept

The Techbuilt house is essentially a house built out of standardized panels. These panels are four foot wide with varying lengths (depending upon their purpose). Everything in a Techbuilt house is a pre-constructed panel--walls, roof, floors, etc. These panels were constructed in a factory and assembled on site. The variation in the type and placement of panels allowed for a variety of design while still keeping costs down. The result was a very sleek, modern looking house that could be erected for about $8 a square foot--at a time when a conventional "stick built" house cost around $10 a square foot. Below is a characteristic example of a Techbuilt.

Attics and Basements

As you may have gathered from previous posts at Instant House, basements are the exception rather than the norm in prefabricated housing. Basements present problems for the designer of the prefabricated house. Techbuilt houses are unique in that Koch chose to sink either the primary living level or the bedroom level 1/2 story below grade, resulting in a "half" basement. This allowed for a proper foundation (below the frost-line), but still left enough usable space above grade for properly sized windows--giving the feeling of a fully finished floor. Koch's concept for the second floor was to leave the space open to the rafters. He called this "putting an attic on top of a basement", which led to a maximum use of space in two of the most problematic (and wasteful) spaces in the traditional house. This is the forerunner of the modern day "bi-level" or "split-level" house. See the diagram at right for an example.

As you may have gathered from previous posts at Instant House, basements are the exception rather than the norm in prefabricated housing. Basements present problems for the designer of the prefabricated house. Techbuilt houses are unique in that Koch chose to sink either the primary living level or the bedroom level 1/2 story below grade, resulting in a "half" basement. This allowed for a proper foundation (below the frost-line), but still left enough usable space above grade for properly sized windows--giving the feeling of a fully finished floor. Koch's concept for the second floor was to leave the space open to the rafters. He called this "putting an attic on top of a basement", which led to a maximum use of space in two of the most problematic (and wasteful) spaces in the traditional house. This is the forerunner of the modern day "bi-level" or "split-level" house. See the diagram at right for an example.

The Construction

As is the case with most stressed-skin panels, they are remarkably light yet strong (think: airplane engineering). Koch claimed that the panels can easily be unloaded by two men--though four is ideal. In his magnum opus work At Home With Tomorrow, he claims that four men working without special equipment can set up the shell and roof of a house in two days time. One gable end and the two side walls are erected and bolted together. The other gable end remains open until the first and second floor panels have been installed. You can see from the diagram at the right how the entire house is framed much like a barn, with very little interior structural members.

As is the case with most stressed-skin panels, they are remarkably light yet strong (think: airplane engineering). Koch claimed that the panels can easily be unloaded by two men--though four is ideal. In his magnum opus work At Home With Tomorrow, he claims that four men working without special equipment can set up the shell and roof of a house in two days time. One gable end and the two side walls are erected and bolted together. The other gable end remains open until the first and second floor panels have been installed. You can see from the diagram at the right how the entire house is framed much like a barn, with very little interior structural members.

Decorating A Techbuilt Home

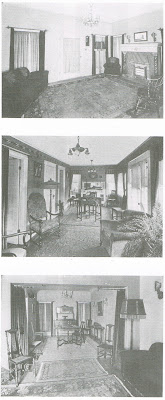

Modernist houses aren't for everyone, and neocolonial or other traditional furniture and decoration styles don't work very well in many modernist houses. Koch himself states that "Techbuilts have never been aesthetically foolproof...The simplicity of the house itself puts some responsibility on the buyer not to overstuff or overdecorate it." As such, Techbuilt attempted to offer its own line of furniture--Techbuilt Spacemaking Furniture. It did work out and proved too costly to manufacture. See the examples at right.

Modernist houses aren't for everyone, and neocolonial or other traditional furniture and decoration styles don't work very well in many modernist houses. Koch himself states that "Techbuilts have never been aesthetically foolproof...The simplicity of the house itself puts some responsibility on the buyer not to overstuff or overdecorate it." As such, Techbuilt attempted to offer its own line of furniture--Techbuilt Spacemaking Furniture. It did work out and proved too costly to manufacture. See the examples at right.

Techbuilt Communities

More on Techbuilt to come, including Vacation Homes! But for now, here are two examples of the "attic-on-top-of-a-basement" homes. Enjoy!