More Lustron Stuff

I recently found a picture on the internet of a Lustron being erected in an urban environment. This has to be the one-and-only Lustron erected as a model home in Chicago. Here is the picture:Check out the building site. For a supposedly "prefabricated house", there sure are a lot of components being assembled on-site! Hang onto that thought...

Lustron's (Almost) Savior

I was scouring Carl Koch's (of Techbuilt fame) book about his history with prefabricated housing - At Home With Tomorrow. Koch was brought on during the last few years of Lustron to re-tool and revamp the Lustron. He devotes a chapter to his stint with Lustron. He identified four key problems with the Lustron product. Quoted from the book:

1. The original Lustron model used four different sizes of window in a fixed arrangement. We reduced them to one--but so designed as to be triple-hung and completely interchangeable with solid wall panels of the same size, so that we could make any combination with these few panels. Putting two such sections side-by-side would permit not twelve but thirty-six variations. Three, side by side, would offer two hundred and sixteen. Not all of them would be useful, needless to say, but the law of combinations is one of the pleasant mathematical secrets of modular planning.

2. Since the enameled walls of the Lustron house were permanent, in and out (the enamel would chip away in places when the house was put together, but was easily patched), it followed that wall color was permanent too. This could be a little hard on a housewife, who, having lived with green surroundings for several years, might suddenly decide she liked brown better, or yellow, or white. If green was what she had selected, green was what she had. So what we recommended was that inside wall color be made as unobtrusive as possible, neutral--shades of gray, in fact. Then the color motif of the house could be established by the housewife herself, by the generous use of color in rugs, fabrics, furniture, drapes, and the like--things that COULD be changed.

3. The original Lustron house was fixed, as to size and interior plan. We discovered, working with a basic size of 29 by 37 feet, and an expanded size of 29 by 45 feet, that Lustron could offer four different interior plans in each, including several for three bedrooms. Any of these plans, moreover, could be "flipped," that is to say, built as a mirror image of itself. And all plans, together, would use the same component parts, with virtually no exception.

4. The number of separate components which would arrive by truck, to be assembled on site by individual builders, we reduced from three thousand to thirty-seven by providing for the assembly of window sections, storage walls, plumbing walls, and so forth in the plant itself. Lustron, indeed, was already on the trail of this simplification.

Re-read number four. 3,000 parts to be assembled on-site???? No wonder this thing didn't take off. One of the three key advantages in prefabricated housing is SPEED. The second is SIMPLIFICATION. 3,000 parts doesn't sound like either. 37 is more like it. Sadly, Koch's Lustron didn't take off in time, and only one model home was ever built. Pics below.

|

| The 1950 Koch Lustron |

|

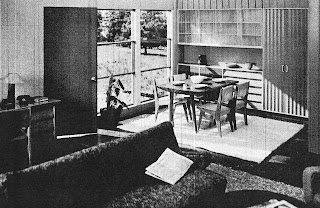

| Living Room |

|

| Dining Room |

|

| Bedroom |

The construction photo was taken in Manhattan, and was a model home. The 3,000 parts could be assembled in as little as three days, but generally, buyers were told it would be two weeks from delivery to move-in. Lustron dealers' trained crews erected them; they were not intended for buyers to assemble. See "The Lustron Home: A History of a Post-War Prefabricated Housing Experiment" Thomas T. Fetters, 2004

ReplyDeleteHi,

ReplyDeleteI came across a Lustron Home in Little Rock Arkansas. Unfortunately, it's in disarray. Sad.

The "Lustron" house at the end of the pictures is one of the rare ALCOA houses that were built with one in perhaps twenty states. This was an Aluminum Company of America project and you can find a limited history on the web. There is one still in great condition in Wheaton, Illinois but several out west have been razed. These were all one-of-a-kind in a plan to interest buyers. The house is very open inside with selected corridors to illuminate the house during the day. A two car garage is part of the designed model.

ReplyDeleteTom Fetters